Elon Musk promises $25,000 electric car at Tesla’s ‘Battery Day’

Tesla

- The high cost of batteries is the main reason why electric vehicles cost more than gas-powered cars.

- At the company’s ‘Battery Day’ event on Tuesday, Tesla announced a new battery design that will give its cars more power and a longer range.

- The success of Tesla’s plan depends on its ability to scale up production.

Cheaper, more efficient batteries. That’s what Tesla says will allow it to offer a $25,000 electric car within the next three years. The announcements came at the company’s “Battery Day” event on Tuesday afternoon in Palo Alto, California.

“One of the things that troubles me the most is that we don’t yet have a truly affordable car, and that is something that we will make in the future,” Tesla CEO Elon Musk told a socially distanced audience, who were sitting in cars in a parking lot. “But in order to do that, we’ve got to get the cost of batteries down.”

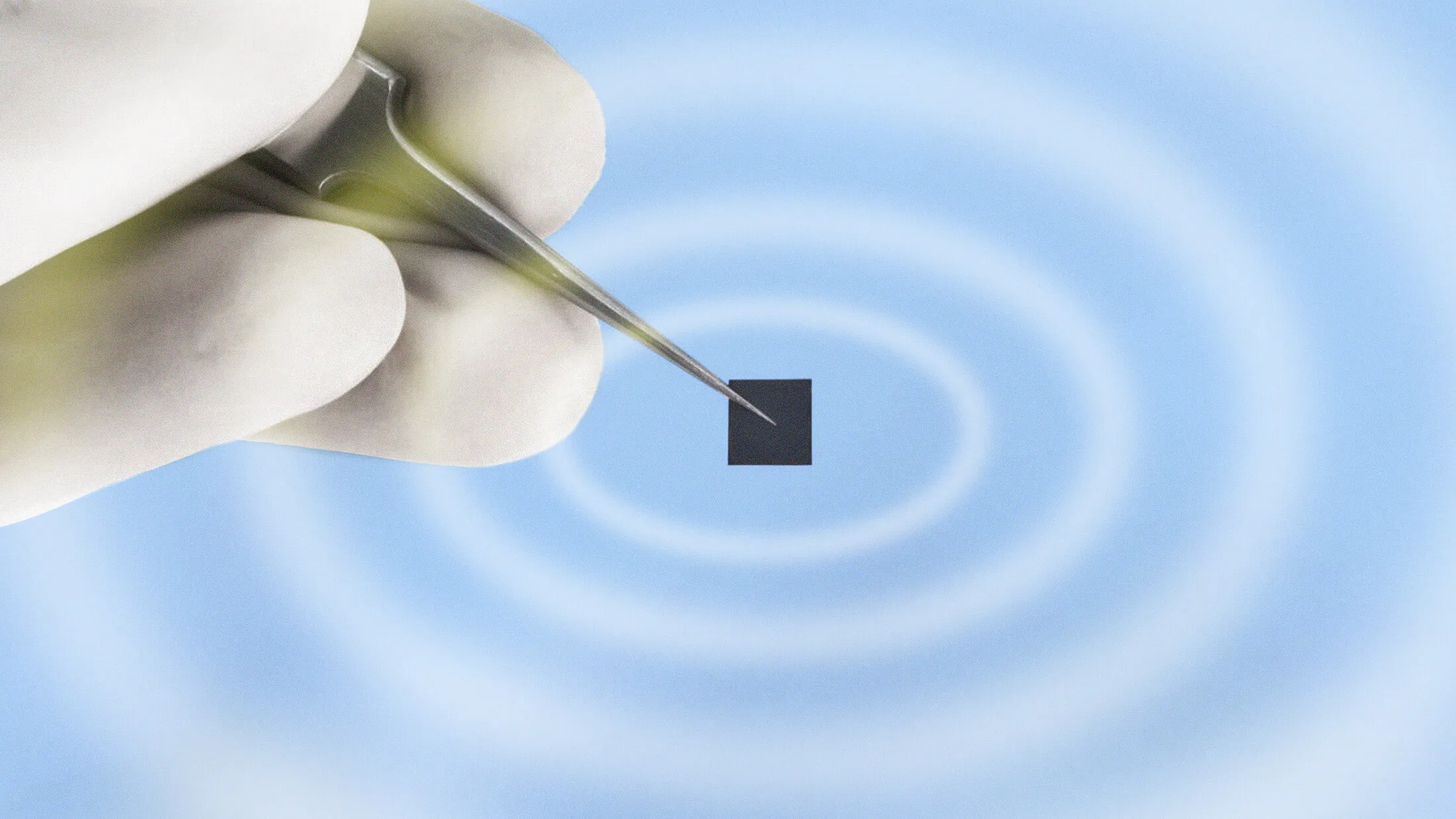

How to cut costs? Tesla is working on a design update for its batteries, and the company plans to begin manufacturing them in-house. (Panasonic currently produces Tesla batteries.) A key design update is removing a tab within the battery that connects the cell to what it powers.

2020 Annual Shareholder Meeting and Battery Dayyoutu.be

“You actually have a shorter path length [for the electron to travel] in a large tabless cell than you have in the smaller cell with tabs,” Musk said. “So even though the cell is bigger, it actually has more power.”

Tesla also plans to lower costs by using nickel instead of cobalt in its cathodes. The company said its new cathode design would reduce costs by about 75 percent, and also remove waste water from the manufacturing process.

What’s more, the international cobalt supply is limited, and most of it comes from the Democratic Republic of Congo, where adult and child miners are known to be exploited.

Screenshot of Tesla’s ‘Battery Day’ presentationTesla

It’s unclear when Tesla will stop using cobalt, or when it will stop sourcing its batteries from Panasonic. But Tesla claims that its new battery design and manufacturing changes will allow it to cut the cost per kilowatt-hour in half. If Tesla can successfully scale up production, the company could hit its goal of $100 per kilowatt-hour sooner than expected.

Hitting that mark could usher in the electric-car revolution, considering $100 per kilowatt-hour is generally regarded as the threshold the industry needs to reach in order to make electric vehicles cost competitive with gas-powered cars.

A $25,000 electric car would also be Tesla’s cheapest offering by far. The company had previously promised a $35,000 car, but only offered one at that price for a limited time. Tesla’s website says its Model 3, its cheapest car, starts at about $39,000.

Photo of Tesla’s new battery designTesla

To be sure, Musk is known for promising big on his projects, but not always following through on the promised timetable. But despite having an “insanely hard” 2020, as Musk said, Tesla’s had a good past couple years.

“In 2019, we had 50% growth,” Musk said at the event. “And I think we’ll do really pretty well in 2020, probably somewhere between 30 to 40 percent growth, despite a lot of very difficult circumstances.”