A behind-the-scenes look at building the greatest telescope of all

How the James Webb Space Telescope was made.

“One way or another the first stars must have influenced our own history, beginning with stirring up everything and producing the other chemical elements besides hydrogen and helium. So if we really want to know where our atoms came from, and how the little planet Earth came to be capable of supporting life, we need to measure what happened at the beginning.” –John Mather

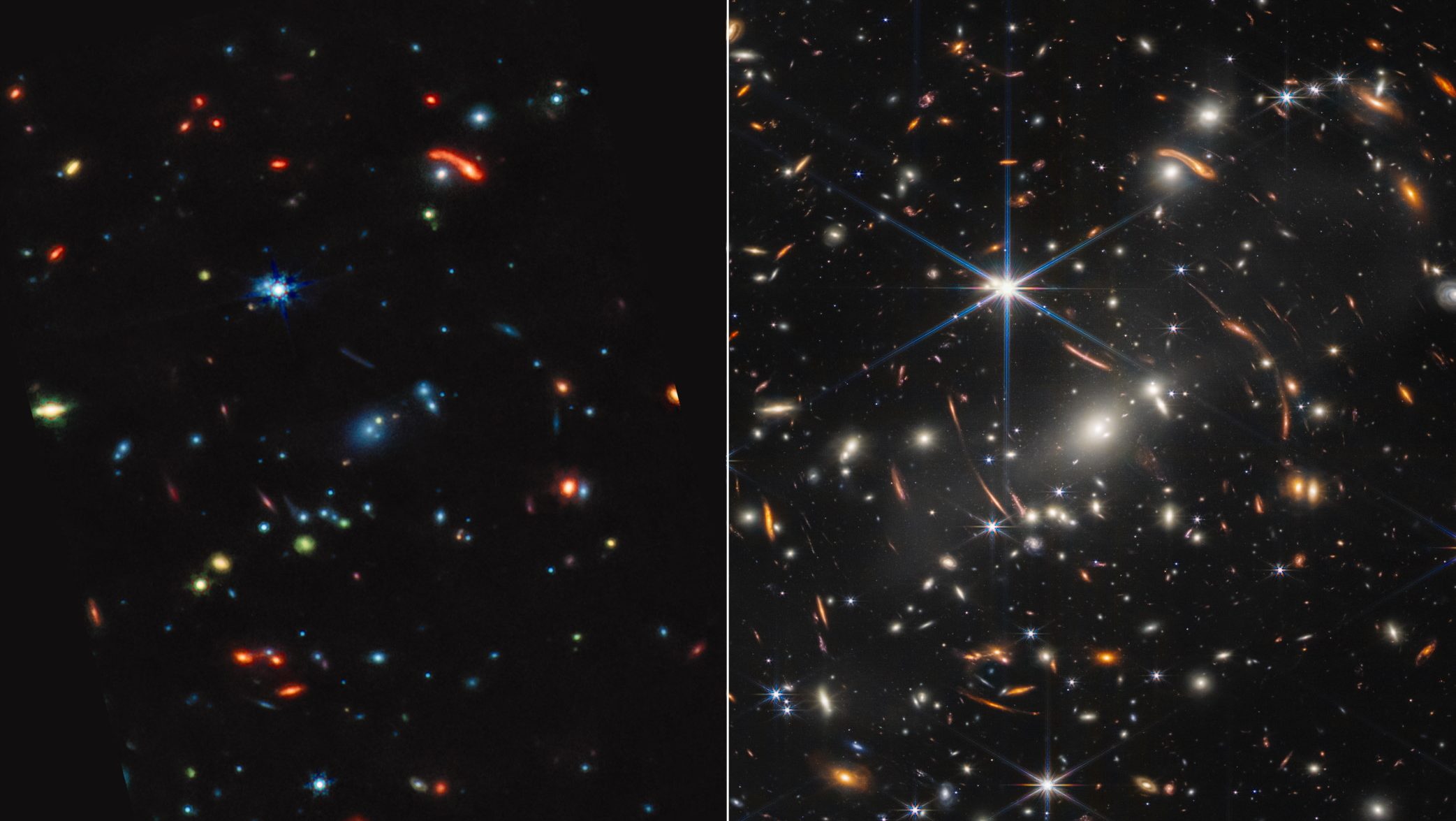

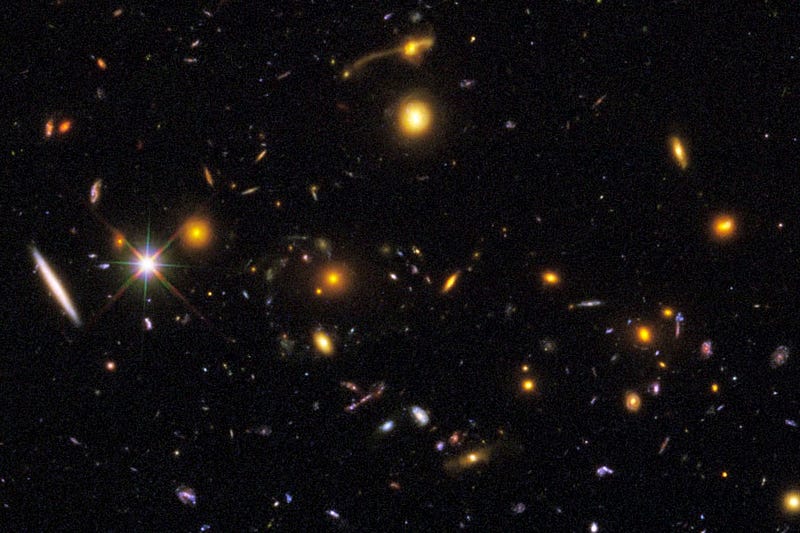

So, you want to see farther back into the Universe than ever before? To discover how it grew up; to measure the first stars and galaxies; to view it in a new way and to higher precision than ever before? In principle, it’s a straightforward challenge. Just build a larger primary mirror to gather more light than ever before, sensitive to longer wavelengths of light than Hubble to see the earliest light stretched by the expanding Universe, with a series of advanced instruments to maximize the information gleaned from the light, cooled down to cryogenic temperatures to minimize contamination. Oh, and do it all in space, on a scale you’ve never done it before. It’s not just science and the scientific instruments that will get you there, but a remarkable engineering story of how to anticipate the unknown and rise to the challenge. To get there, you have to view things differently than how even a scientists would view them. I had a chance to sit down with Jon Arenberg, the Chief Engineer for Northrup Grummon’s James Webb Space Telescope, and get a hint of exactly how this works through his eyes.

Take a look at the picture above, and what do you see? Perhaps you see the space shuttle. Perhaps you see the space shuttle Columbia, launching at night. But to Jon, he sees something else: the space shuttle launching with his satellite aboard it. Before he began work on James Webb, Jon helped build the Chandra X-ray Observatory, which has been operating successfully for the past 18 years. One of the challenges you don’t think of with a space telescope is that it has to fit inside the launch vehicle, which places additional restrictions on the manufacture, mounting, the design of enclosure, and electromechanical design of everything on board. You have to plan for every stage — stowed design, launch, decompression, deployment, exposure to the vacuum of space and a lifetime of operations — from the very beginning. And every project has its own unique challenges.

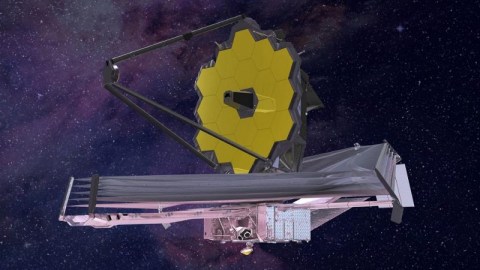

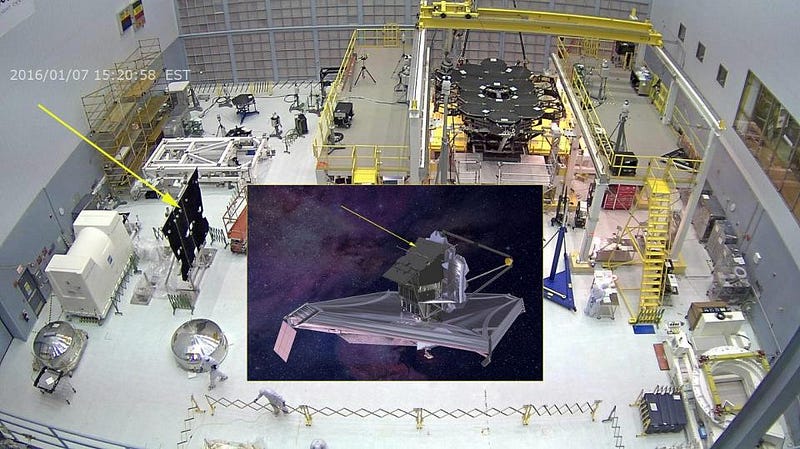

For the James Webb Space Telescope, it seems like every challenge is unique. The architecture of the telescope is wholly new to spaceflight. The open architecture for cooling, where the craft is passively cooled and shielded from the Sun, is new. The five-layer sunshield is new, and had to be designed from scratch. This is the first multi-segmented mirror in space, meaning that not only is the design unique, but the deployment required an entirely new design as well. And the operation of the telescope — the unfolding sequence — is itself a marvel of engineering.

https://www.youtube.com/watch?v=bTxLAGchWnA

Designing and building a telescope like this, rife with novel challenges never before faced by humanity, is a challenge in more than just the engineering sense. You need to estimate how much time, money and resources you require to build it. You can’t count on things working the way you designed them the first time; you can’t count on your initial work passing all of the stress tests; you can’t count on a smooth integration with a system that has yet to be designed. You need to estimate the “unknown unknowns” when you’re first designing your budget, and you need to build a team that not only excels at what they do, but that excels at identifying and solving problems they couldn’t have anticipated would exist.

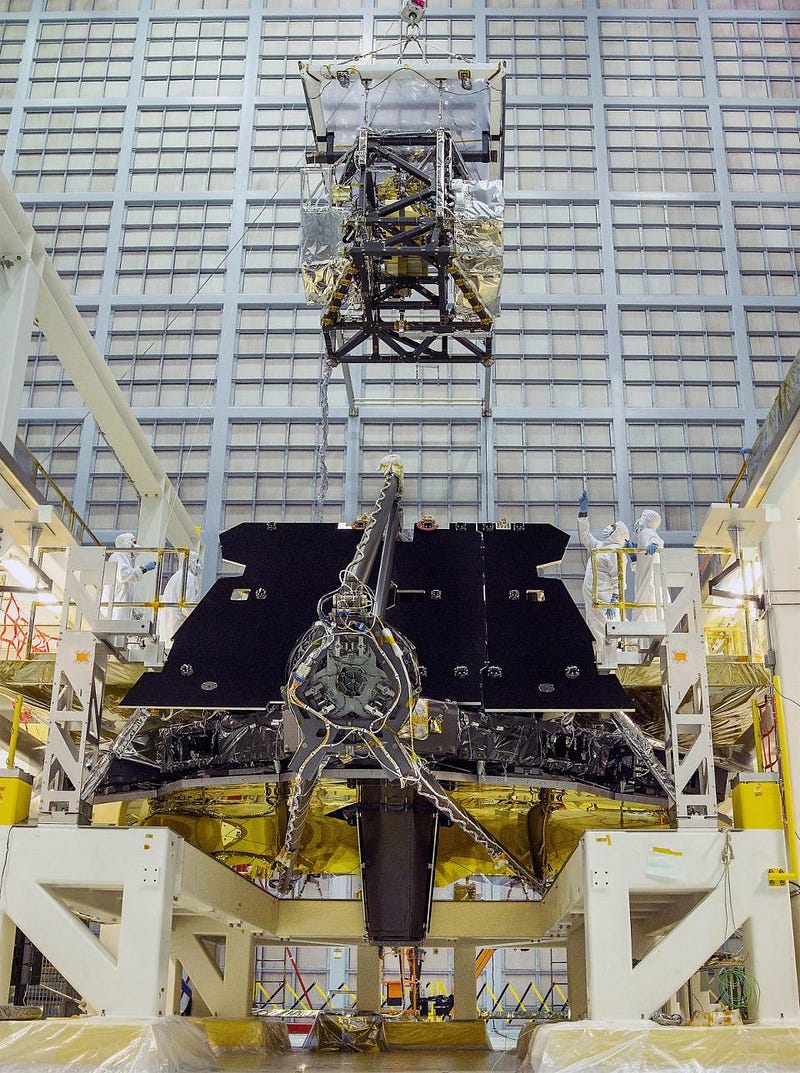

In addition, the different components all reach their stage of completion at different times. The four main science instruments were all built independently, by American, Canadian, European and other international partners. The ISIM module was built at Goddard and integrates all the instruments with the rest of the spacecraft. The scientific bounty in the near infrared, in spectroscopy, in the ability to point better than ever before (to better than a millionth of a degree), and in sensitivity will be unparalleled. But the other components — the mirrors, the sunshield and the assembly — all have a slew of unique challenges as well, that you might never have thought about having to face.

The Mirrors. When you manufacture a telescope mirror on Earth, you can make it under the same conditions you’ll be using it. But in space, at infrared wavelengths, you need to manufacture a segmented structure that acts like a smooth, single surface to a tolerance of 20 nanometers. It needs to be light weight for launch, and it needs to be structurally sound. To make these mirrors, they manufacture a smooth surface at room temperature, but design it to have the necessary properties at below-liquid-nitrogen temperatures. They manufacture it under Earth’s gravity, but at these scales, even the deformation of gravity matters; the mirrors will operate in the zero-gravity environment of space. They create the smooth, polished, coated surface at the front but machine away 92% of the back, creating a 25-square-meter surface with just 6.25 metric tonnes of material: more than seven times larger than Hubble but just 55% of Hubble’s mass. The fundamental challenge is that you can only make measurements in your own controlled environments and orientations, but you need to manufacture the mirrors to operate under spaceflight conditions. Once you make the first successful mirrors — the ones that pass all the tests under operating conditions — the mirrors wound up coming off with astonishing regularity.

The Sunshield. It’s always a challenge to develop a completely novel architectural element. Up until JWST, all infrared space telescopes have been actively cooled: you bring up some coolant and put your telescope in a cryogenic cooler. But this telescope is too big for that! So they instead designed and built a series of layered shields to permanently shield the telescope from the Sun: JWST will have a “sun side” that the sunshield and solar panels face, and a “shade side” that houses all the instruments and mirrors. The hot end of the hot side is 350º C (662º F), or hot enough to melt lead, while the cool side, on the other end of the five layers, needs to be colder than liquid nitrogen (77 K). Monumental challenges included how to vent the heat (out of the sides), how to evacuate all the air during launch without ripping the shield, how to make holes that align while it’s stowed but don’t overlap while it’s deployed, and how to fold the sunshield to eliminate the possibility of a snag during deployment. The ultimately successful design was a culmination and a combination of modern simulations/calculations, and old-fashioned pattern/sail/dress-making techniques; it was a unique mix of cutting-edge technology and artistry. In the end, it’s just five layers of coated plastic, but if it works as designed, it will keep James Webb operating long beyond its designed five-year lifespan.

The Assembly. This is what you generally think of as the spacecraft itself. The assembly holds up the entire observatory at launch, it controls and points all of the different instruments, mirrors, antennae and more. It’s responsible for the data collected, received and transmitted; it’s responsible for handling and pointing the spacecraft. But one unique challenge it faces is that running electricity through the assembly itself and moving various parts of the spacecraft generates heat, and it generates heat on the wrong side of the sunshield! The telescope is pointing away from the Sun, so you can’t dump your waste heat there, while there’s no shade (and no place to dump heat) on the Sun-facing side. The solution involved developing a series of shades to protect the critical parts of the observatory — the parts that must be kept cool — from the other parts of the spacecraft. Successfully finding, designing and executing the ultimate solution was one of the biggest thrills an engineer can experience in their careers.

Yes, the science will be incredible. As Garth Illingsworth said about this telescope, “we’re going to learn more in one day from James Webb Space Telescope than mankind currently knows” about the first galaxies in the Universe. Just like the “Hubble Key Project” wasn’t even the greatest find that the Hubble Space Telescope made, perhaps with its unique capabilities, JWST will reveal even deeper secrets about the Universe than what we know to look for. In less than two years, we’ll begin to find out. But without the team of engineers who designed, built and executed all of this to exquisite precision, we wouldn’t have any of it at all. And after October of 2018, Jon Arenberg and everyone who worked on James Webb will have a new picture to share.

An Ariane 5 rocket, launching at dawn, will carry James Webb in full sunlight to its destination: the L2 Lagrange point, beyond the shadow of both the Earth and the Moon. For only 32 minutes, James Webb will be under battery power; after that, the solar arrays deploy and it will forever be in direct sunlight. Its mission to reveal the Universe will have begun, and every scientist and engineer who helped design and build it will get their celebratory moment of a lifetime.

This post first appeared at Forbes, and is brought to you ad-free by our Patreon supporters. Comment on our forum, & buy our first book: Beyond The Galaxy!