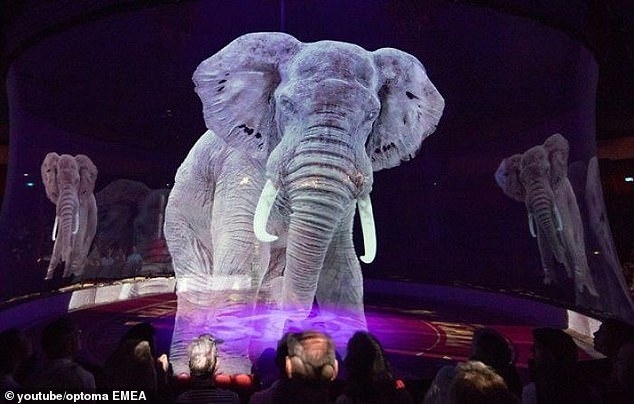

German scientists 3D print objects with “acoustic holograms”

In research that sounds more X-Men than academic, teams based at Germany’s Max Planck Institute for Medical Research and Heidelberg University have developed a way to 3D print objects, in one shot, using sound waves.

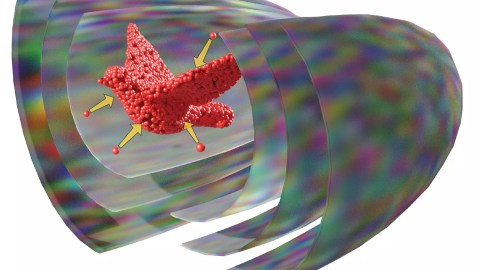

The concept, published in Science Advances, uses shaped ultrasound to create “acoustic holograms,” which put pressure on the printed medium and mold it into shape — sort of like an invisible mold.

“We were able to assemble microparticles into a three-dimensional object within a single shot using shaped ultrasound,” said study first author Kai Melde.

In research that sounds more X-Men than academic, teams have developed a way to 3D print objects, in one shot, using sound waves.

The team was able to use their technique to print 3D objects from solid microparticles, hydrogel beads, and even biological cells — contact-free (bar the sound waves, of course).

Sound can be used to form objects because sound waves exert force; think of the pressure you feel standing in front of a massive speaker stack at a show (also, put your earplugs in!) or a sonic boom from a supersonic aircraft. The shaped ultrasound used by the researchers resonates at a high frequency that is inaudible to the human air, and can be pushed into microscopic levels, able to manipulate extremely tiny media, like cells.

Building on previous research using ultrasound to print in two dimensions, the new technique uses multiple “acoustic holograms” — made with intricately designed plates meant to produce a certain sound wave shape. By surrounding the material, they create a field which gathers it up and then forms whatever shape you want printed. Kind of like using your hands to make a snowball — but, like, with ultrasound and at a cellular level.

Going from 3D model to ultrasound field was quite difficult, requiring a custom algorithm to pull it off, said Heiner Kremer, who wrote the program.

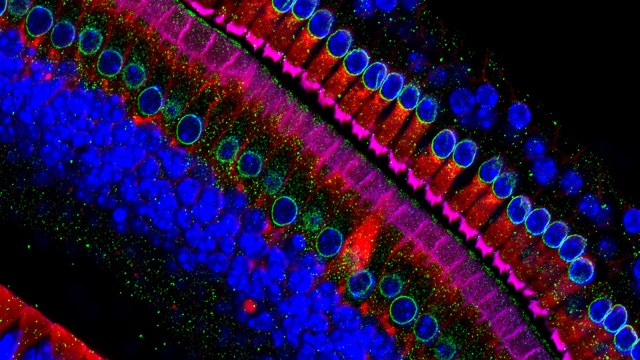

Using the shaped ultrasound, the team was able to capture and shape particles and cells suspended in water with one go.

The sound waves do not damage cells, meaning that chemical additives are not needed, so the technique might be especially useful at 3D bioprinting tissues and cell cultures.

Crucially, the sound waves do not damage the cells, meaning that chemical additives are not needed, so the technique might be especially useful at 3D bioprinting tissues and cell cultures. Ultrasound waves can also penetrate deep into tissues, allowing for more cell-friendly manipulation.

“This can be very useful for bioprinting,” Heidelberg professor Peer Fischer said. “The cells used there are particularly sensitive to the environment during the process.”

This article was originally published by our sister site, Freethink.