The First Store That Runs on Its Own Food Waste

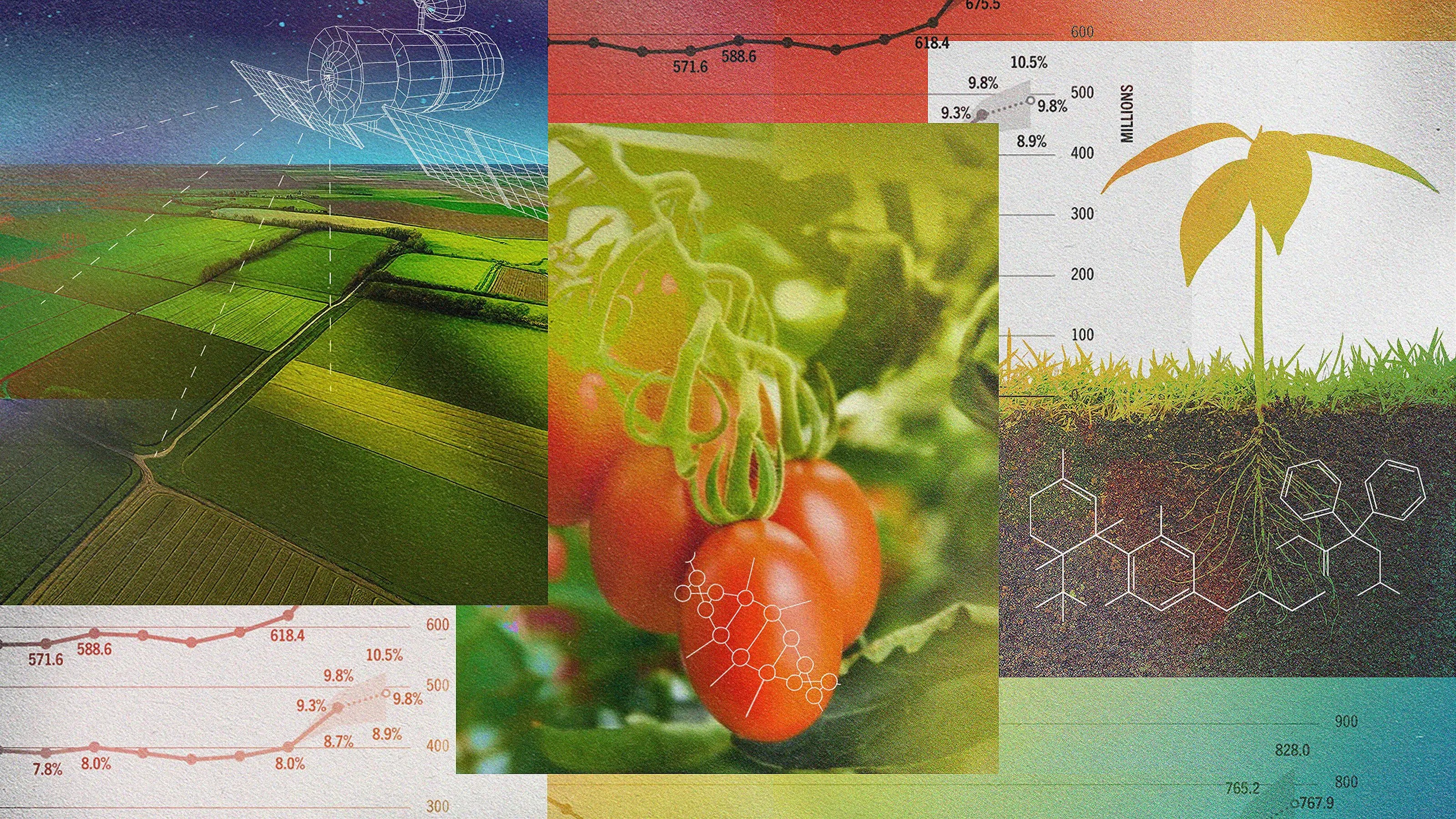

According to the UN a third of the food the world produces is wasted, the monetary equivalent of $750 billion. Food loss and waste amount to a major squandering not only of capital, but also of resources, including water, land, energy, and labour as well as needless production of greenhouse gas emissions. Addressing the issue of food waste requires interventions on all levels — from consumer behavior (especially in developed countries, where a big percentage of food waste comes from households), to better business practices, strong political will, and legislation.

One business making a commendable effort to address the problem is Sainsbury’s — the second-largest chain of supermarkets in the UK. Sainsbury’s has managed to achieve zero waste to landfill since June 2013. This means that all its store waste is diverted from landfills by donating, recycling, or turning it into fuel. Food that is not in good enough condition to be donated to charities is processed into animal feed to support British farmers. What is left is turned into bio fuel through a partnership with the waste management company Biffa.

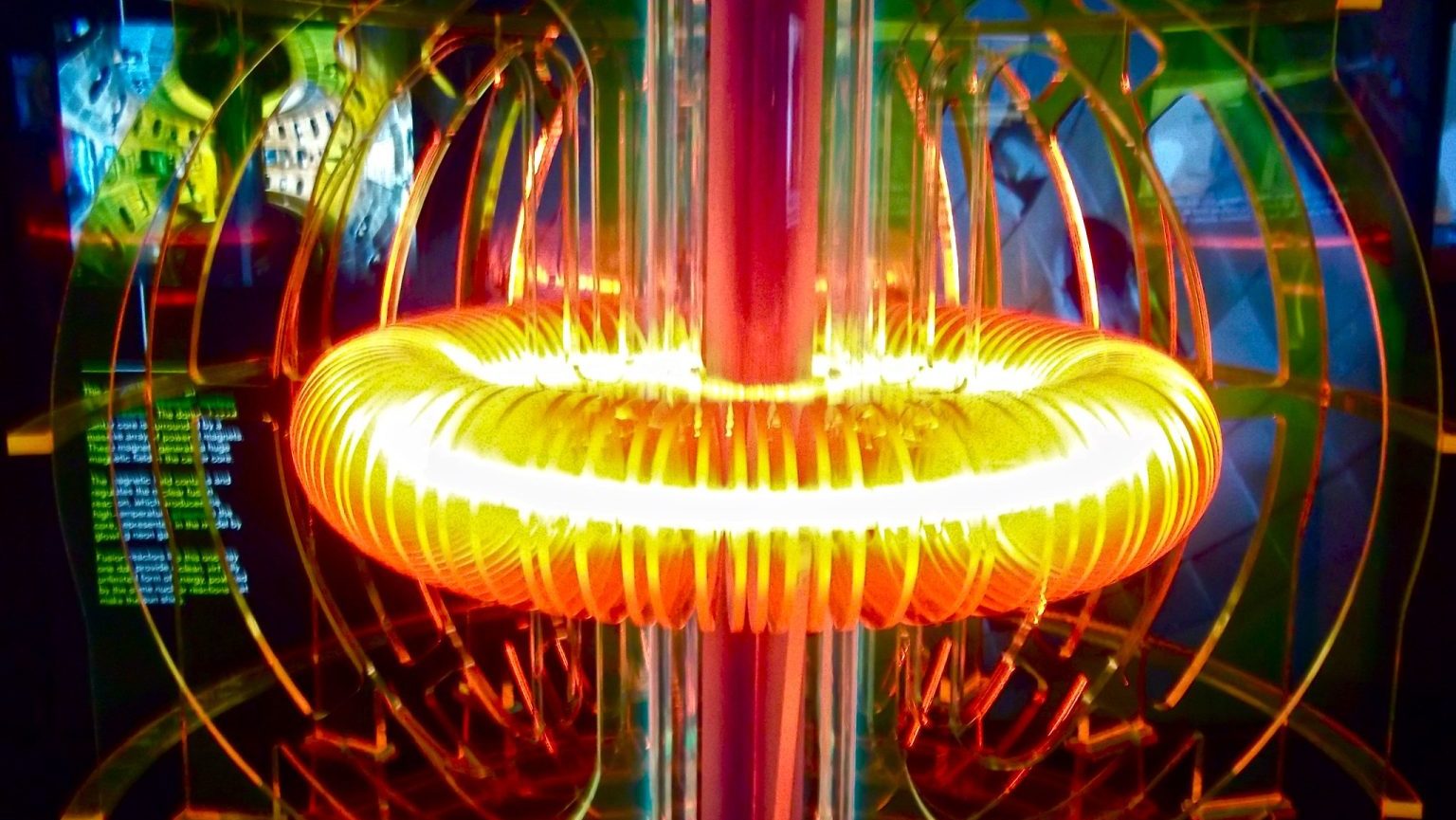

Last year Sainsbury’s and Biffa launched an innovative facility that allows one Sainsbury’s store in Cannock to run on power generated entirely from the supermarket’s own food waste. Biffa’s largest plant is located in Cannock, featuring advanced anaerobic digestion (AD) technology that turns food waste into bio-methane gas. The food waste that Sainsbury’s sends to Biffa’s facilities generates enough energy to power 2,500 homes each year. Now the Cannock store has its own designated 1.5 km-long electricity cable running from Biffa’s facility to the store, which supplies it with electricity and allows it to come off the national grid for day-to-day operations. Closing the loop even further, a by-product of the AD process is sent to local farmers to use as fertilizer.

According to The Guardian, the project involved an investment of around £280,000 for installation of power cables, switchgears, and legal fees. Yet the retailer estimates that, in one year, it may save £140,000 in reduced energy costs thanks to the project.

“Sainsbury’s sends absolutely no waste to landfill and we’re always looking for new ways to re-use and recycle,” said Paul Crewe, head of sustainability at Sainsbury’s for the BBC. ”We’re delighted to be the first business ever to make use of this link-up technology, allowing our Cannock store to be powered entirely by our food waste.”

While this particular strategy may not be suitable for all kinds of retailers, let’s hope we see more good examples like this, as businesses become more innovative and sustainability-conscious. Now, for a more “entertaining” overview of the food waste problem in the U.S., watch the brilliant John Oliver.

Photo: Shutterstok