This First-Ever Plant Sucks CO2 out of the Air and Feeds It to Vegetables

While there are those who wish to debate the causes of climate change and how much humanity has contributed to it, others look to address greenhouse gas emissions through technology. A first-of-its-kind commercial plant started to operate recently in Switzerland that sucks CO2 from the air to sell to buyers.

The Climeworks AGplant near Zurich is the first one to capture CO2 on an industrial scale, selling about 900 tons of the gas per year to help grow vegetables. That’s how much carbon dioxide 200 cars would release.

Climeworks sees this as a first step, with the company’s goal being to capture 1% of the global CO2 emissions by using this kind of negative emissions technology. Their long-term objective can be achieved with an additional 250,000 plants like this one.

The company touts the scalability of its plants as a favorable factor in achieving their goals.

“Highly scalable negative emission technologies are crucial if we are to stay below the 2-degree target of the international community,” said Christoph Gebald, co-founder and managing director of Climeworks.

Preventing temperatures from rising more than two degrees Celsius is the target set by the Paris agreement on climate change.

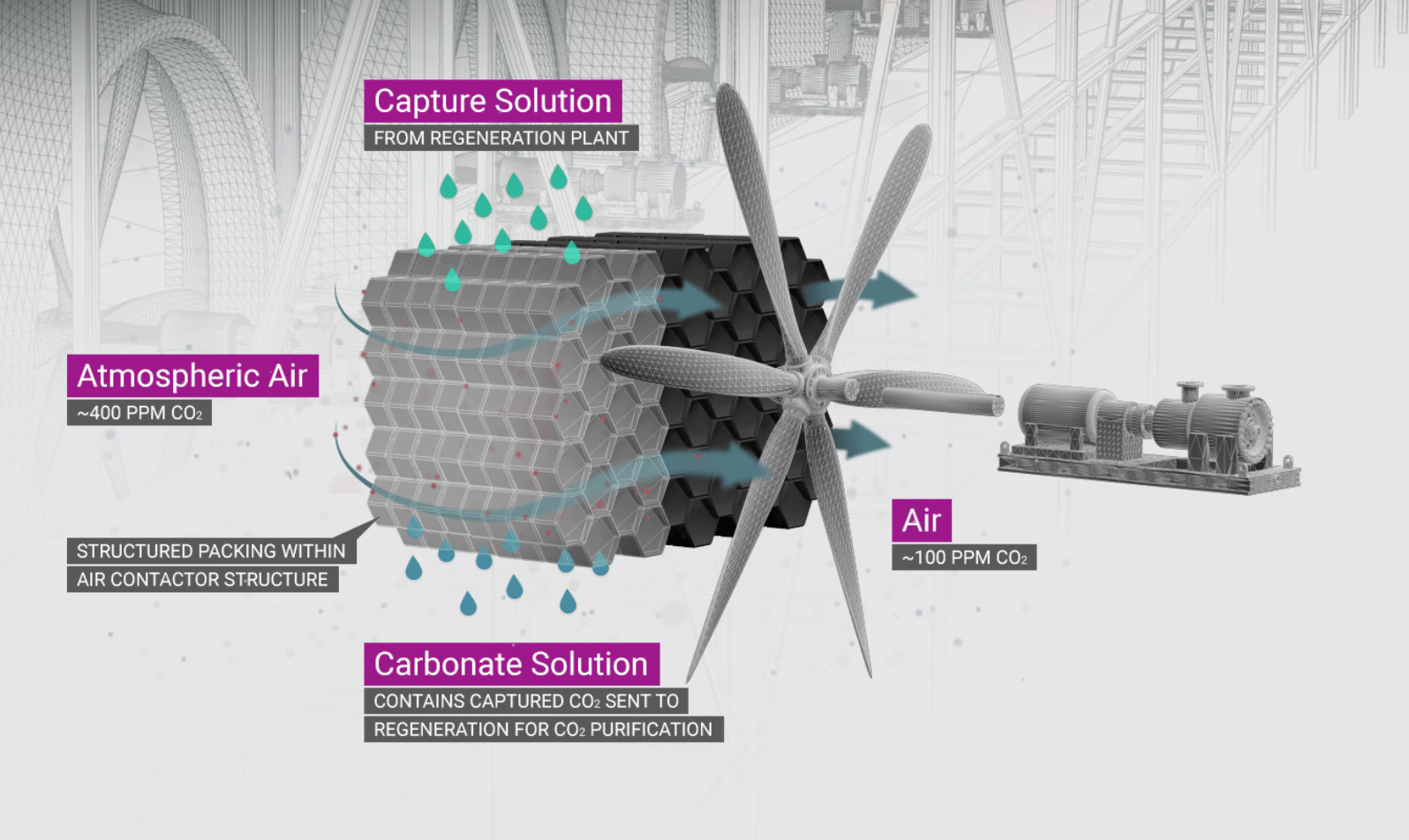

The plant is situated atop a waste heat recovery facility which also powers it. Giant fans push air through a filter that collect CO2, which is then separated out at higher temperatures. The gas is subsequently delivered via an underground pipeline to the customer, which in this case is a greenhouse that grows vegetables like tomatoes and cucumbers.

“You can do this over and over again,” said Climeworks co-founder Jan Wurzbacher to Fast Company. “It’s a cyclic process. You saturate with CO2, then you regenerate, saturate, regenerate. You have multiple of these units, and not all of them go in parallel. Some are taking in CO2, some are releasing CO2. That means that overall the plant has continuous CO2 production, which is also important for the customer.”

Other uses for the CO2 include carbonated drinks, “climate-neutral” fuels and others.

The goal for Climeworks is to run the first plant as a three-year demonstration project, while launching additional commercial installations. Another idea from the company to achieve negative emissions is to bury the gas underground.

“With the energy and economic data from the plant, we can make reliable calculations for other, larger projects,” said Wurzbacher.

Some critics of the project think that it would be cheaper to capture CO2 directly at fossil fuel plants, when it’s more concentrated, instead of trying to get it from the air. The Climeworks founders see their technology as one of the slate of necessary approaches to address emissions. They also point out that their plant is more efficient and leaves less of a carbon footprint than planting trees that would process a comparable amount of CO2.

The Climeworks plant outpaces a Canadian plant backed by Bill Gates in the race to become the first to industrialize the CO2 capture process. That pilot plant is still in the testing stage in British Columbia.

See how the Swiss plant was built and learn more about Climeworks here: