Decorative Solar Panels Produce Energy from Indoor Lighting

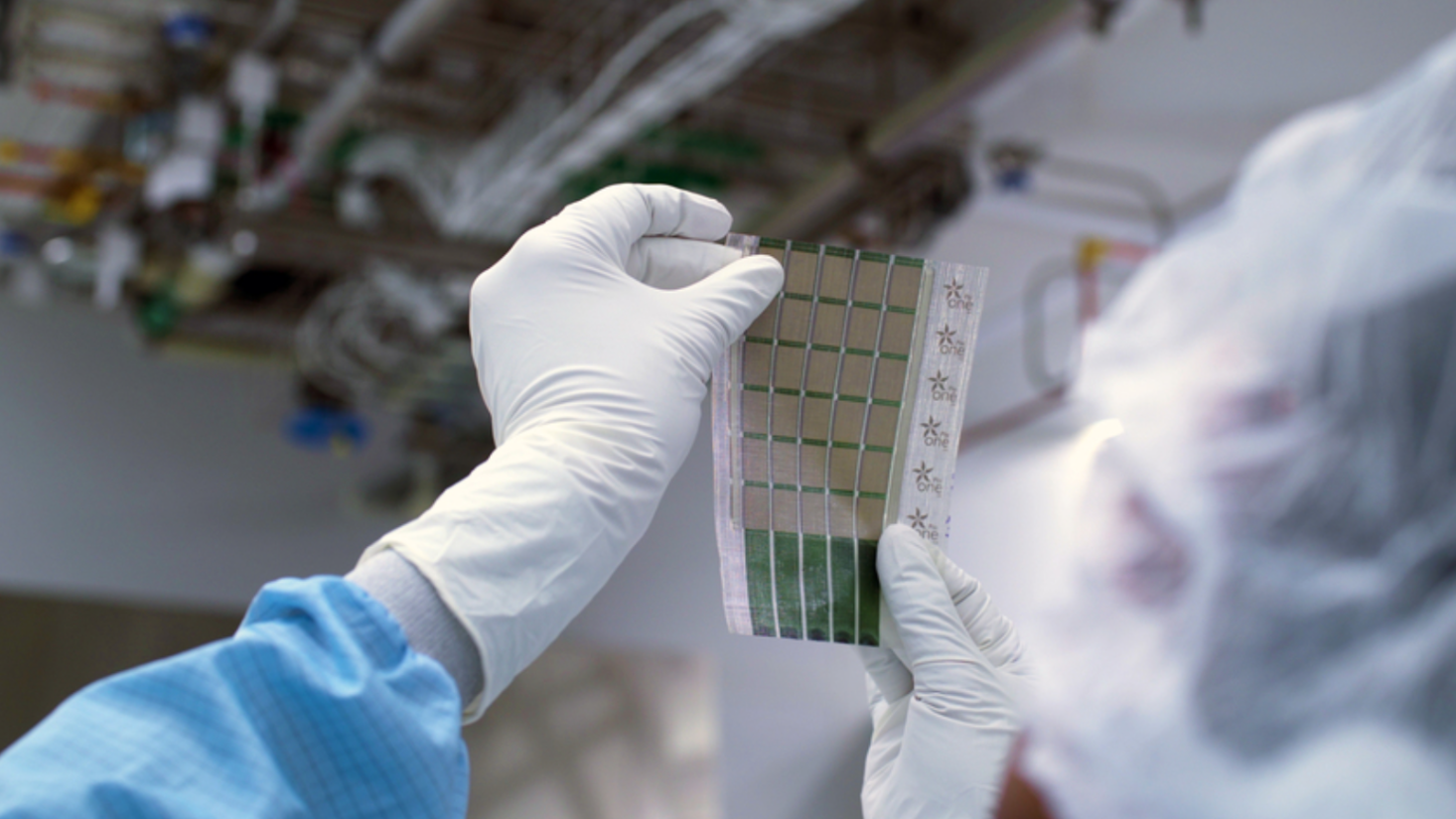

We know that roofs are perfect for solar panels, but how about windows, walls, billboards, and even furniture? The leading research and technology company in the Nordic countries, VTT Technical Research Centre in Finland Ltd, has developed a mass-production method that allows the manufacturing of decorative organic solar panels that can be used on a variety of surfaces.

The organic solar panels (OPV, organic photovoltaics) are only around 0.2 mm thick and can harvest energy from both sunlight and interior lighting. Since the production method is based on technologies that allow for graphics to be printed on the panels, they have a wide range of uses — the panels can be placed on windows, walls, machines, devices, furniture, advertising billboards.

Even though the efficiency of organic solar panels is lower compared to conventional, rigid silicon-based solar panels, they also have many advantages. They are flexible, light, and can be rapidly and affordably mass-produced, using commercially available materials. The lifespan of a panel is a few years, which is enough for many applications, after which it can be fully recycled.

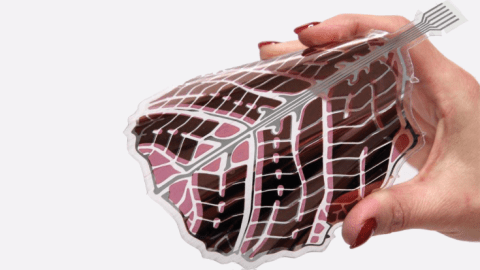

The research scientists at VTT have already tested the printing method by producing leaf-shaped photovoltaic cells. The active surface of one leaf is 0.0144 m2 and includes connections and a decorative part. Two hundred OPV leaves make one square meter of active solar panel surface that generates 3.2 amperes of electricity with 10.4 watts of power at Mediterranean latitudes.

Currently, VTT is commercializing its manufacturing technology with different operators, and is actively seeking new final-stage appliers of the technology.

More here.

Photos: VTT