Is Reshoring for Real?

We’re hearing a lot about jobs coming back to America – reshoring. Is that phenomenon real? I think that what we’re seeing is a rebalancing of the tradability equation. Let’s talk about tradability. That’s a term that the economists gave us. Tradability of a good tells you to what extent is a good that is consumed locally need to be produced locally. Things that are tradable are most consumer products. Restaurant meals and haircuts are not very tradable. Ready mix cement is not very tradable because I have to use it usually within an hour of the time that I produce it.

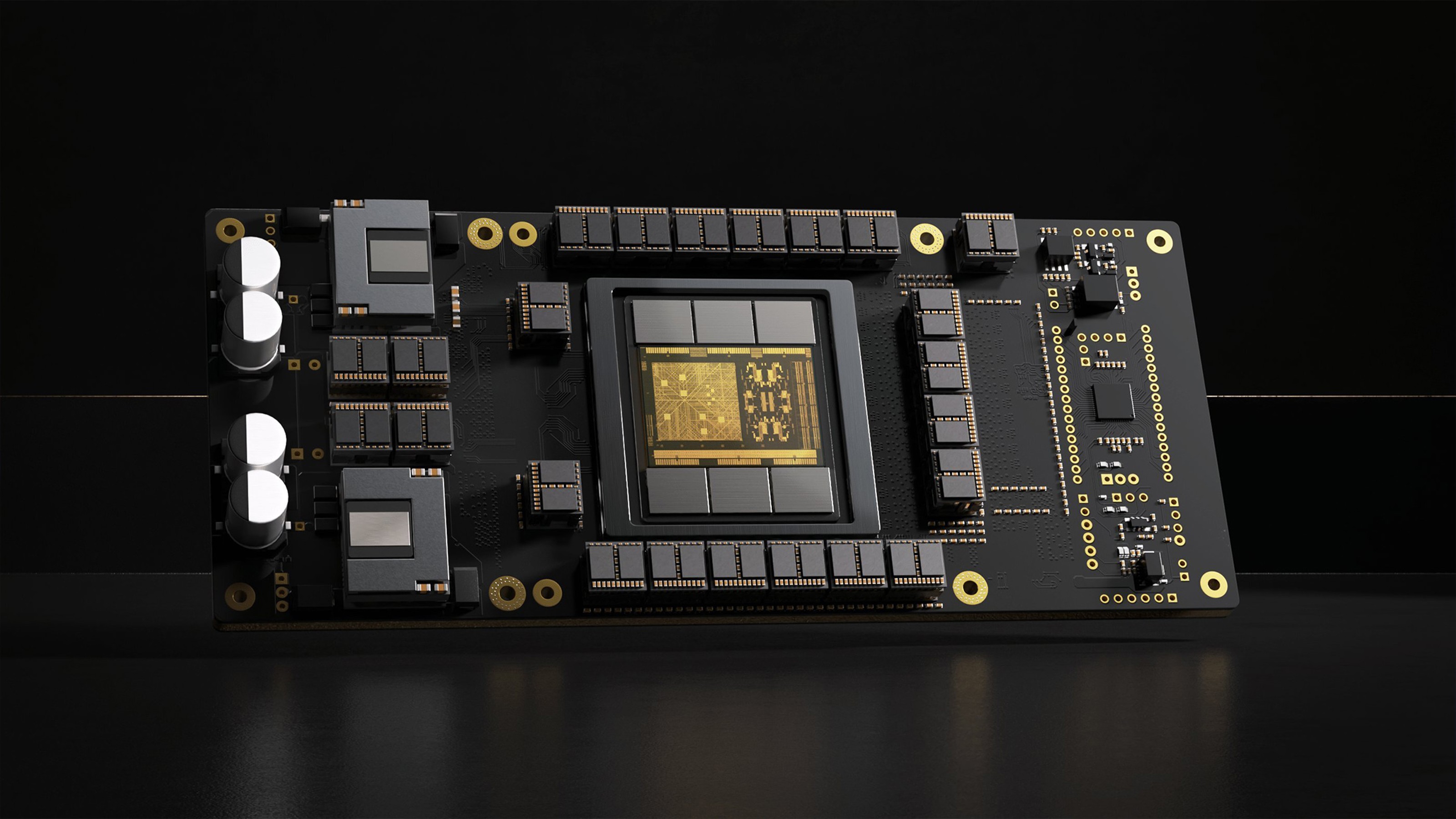

But goods that have a high value relative to the cost of shipping them are readily tradable. Semiconductors, most electronic products, an awful lot of consumer goods, shoes, clothing – these are all very tradable. Back in the 1980s I think the Japanese taught American manufacturers the value of having production right next to R&D. But as China opened up in the early 90s, one of the things that we saw was the labor cost differential was so big that I could take work here and I could ship it off to Asia and I would save a lot of money in my production costs. In fact, I would save so much money we used to talk about throwing labor at the problem because I could throw ten times as many employees at any given task and I would still be ahead of the game.

I think what’s happened over the last five years has been a steady increase in labor costs. In China they’ve gone up on average of around 20 percent a year for the last five years. Costs in the U.S. have been relatively flat. Transportation costs have gone significantly with the price of oil. So I think what we’re seeing is a rebalancing of the tradability equation because while it might have made sense ten years ago to ship a lot of the work to China and take that long supply chain risk and that long inventory pipeline and incur those coordination costs of sending my engineers over to those factories in Asia, I think people are now saying, “You know, with the cost differential that’s not so high anymore, I’m not sure I want to incur all those costs.”

And I think that’s what’s driving a lot of work coming back to the U.S. The key question will be how sustainable is that and will manufacturers in this country recognize and take advantage of and further exploit the benefits of having production close to manufacturing?

In Their Own Words is recorded in Big Think’s studio.

Image courtesy of Shutterstock