3D Printing (Additive Manufacturing) Is Turning the Impossible Into the Possible

What if you could deliver your product to your customer the moment it was manufactured? What if your customers could manufacture a replacement part whenever they need one? What if doctors could manufacture a body part, personalized for the individual patient, in the hospital at a moment’s notice?

Thanks to 3D Printing, you can!

I have been covering 3D Printing (also called Additive Manufacturing) for over 20 years in my Technotrends Newsletter, and at first the technology was used for rapid prototyping. Over the past few years, however, rapid advances in processing power, storage, and bandwidth have catapulted this technology into a tool for manufacturing finished products that include jewelry, shoes, dresses, car dashboards, parts for jet engines, jawbones for humans, replacement parts for synthesizers, and much more.

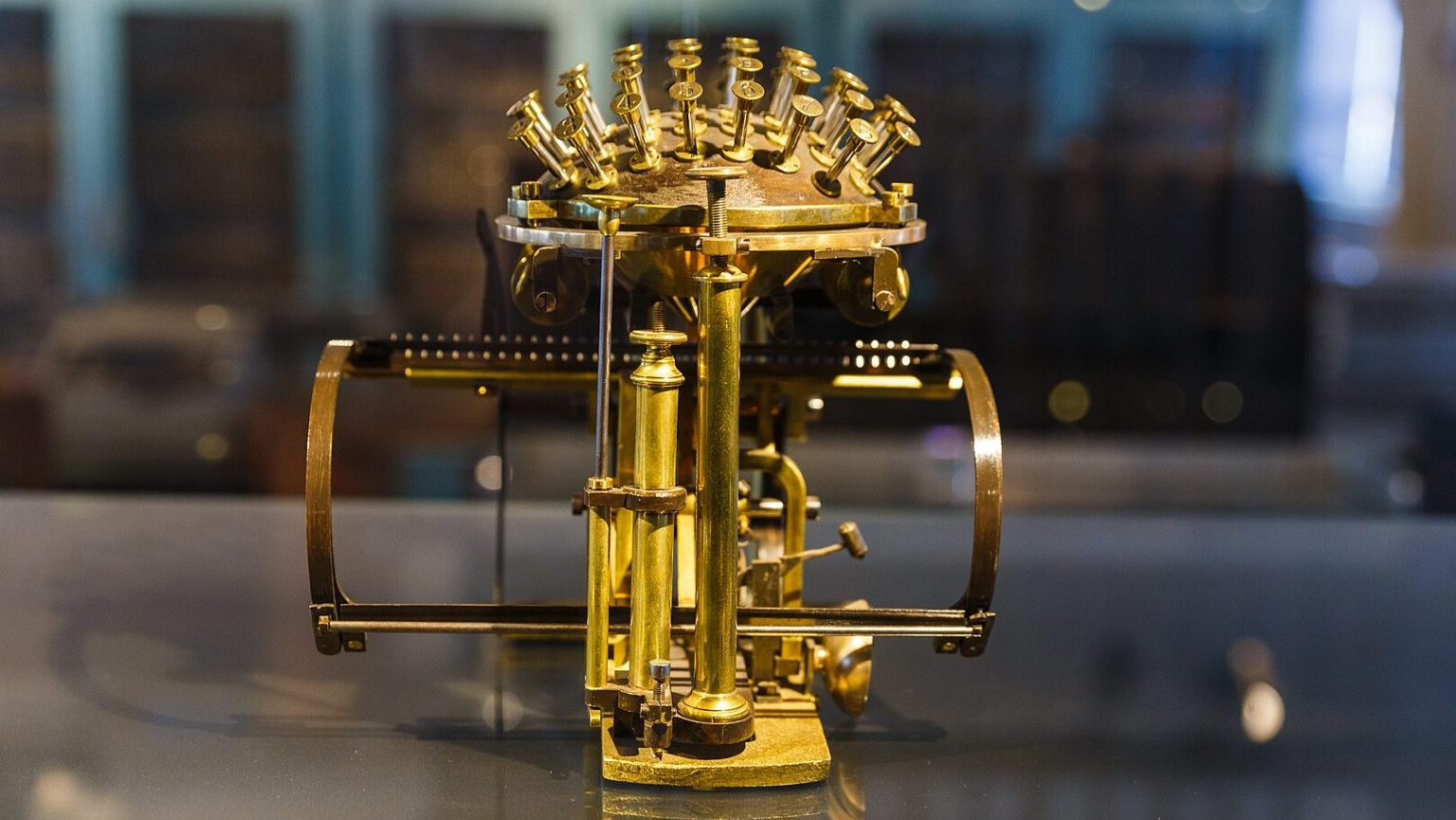

When people first hear that you can manufacture something by printing it, they have a hard time visualizing it. Think of it this way: 3D Printers build things by depositing material, typically plastic or metal, layer by layer, until the prototype or final product is finished. When the design is downloaded into the printer, a laser creates a layer of material and fuses it. Then it adds another layer and fuses it…and then another and another…until the object is completed.

For example, a Belgian company, LayerWise, used 3D Printing to create a jawbone made of titanium that was recently implanted into an 83-year-old woman. An Australian company, Inventech, has created what they call their 3D BioPrinters to print tissue structures using human tissue. And Bespoke Innovations is using 3D Printing to create prosthetic limb castings.

This amazing technology can also be used for on-demand printing of spare parts—something the U.S. military is already doing in the field. Knowing this, it is not hard to see that in the future, a manufacturer could sell a machine or system to a company, and as part of their maintenance and support contract they can put their 3D Printer on-site with the licensed software to print replacement parts as needed.

On a smaller level, it is easy to see that service mechanics will have portable 3D Printers in their vans or at their main office. Original equipment manufacturers (OEM) will most likely sell and license these printers to their dealer network.

In addition, there are already a number of companies including Shapeways and Quirky that will use their 3D Printers to print the design you send them, and then they’ll ship the final product to to you or your customer. It’s not hard to see that at some point Amazon will provide this service too.

3D Printing will definitely become more commonplace in the near future thanks to its many benefits, including the availability of open source computer aided design (CAD) software for designing the part you want to print. In many cases you also have the ability to print the complete part without assembly as well as the ability to print complex inner structures too difficult to be machined. Another great benefit is the entire process produces much less waste than traditional manufacturing where large amounts of material have to be trimmed away from the usable part.

One of the ways manufacturers in the United States and other countries have been able to compete and win business from the low cost mass manufacturers in China has been to focus on short, customized products that can be manufactured and delivered quickly. 3D Printing takes this to the next level by allowing designers and manufacturers to offer personalized manufacturing. This does represent a fast moving revolution in manufacturing that will not be hampered by location or large startup costs.

Whether you call it 3D Printing or Additive Manufacturing, it is advancing quickly on a global level and offers something that up until recently was impossible: On-demand, anytime, anywhere, personalized manufactured items by anyone.