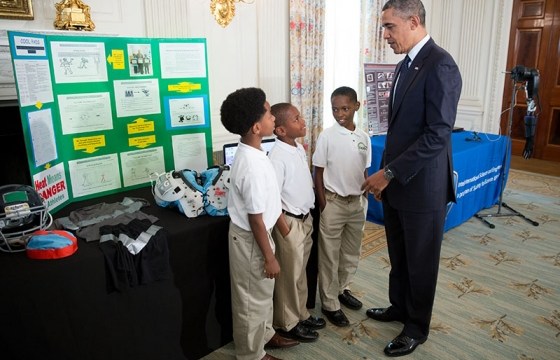

What is Holding Back 3-D Printing?

What’s the Latest Development?

The manufacturing revolution that 3-D printing was meant to facilitate has stalled. Given that much of the printing hardware is decades old, fault lies with 3-D printing software, says Matthew Griffin, director of community support at Adafruit Industries, an online marketplace for high-tech hobbyists. Griffin says that few consumers can operate current software used to render objects. “A lot of people are 3-D printing other people’s designs, but they can’t yet model their own. They are in a holding pattern. There is a gap between what they are seeing and what is inspiring them and what they can make.”

What’s the Big Idea?

3-D printing works by creating layer after layer of objects, from jewelry to sculpture, much as a traditional printer sprays ink onto paper. Currently, however, 3-D printing is not nearly competitive with production costs in developing countries. Making a plastic apple costs seven hours and $50 in materials using state of the art printing technology (which itself costs over $2,000). Could current roadblocks be overcome, however, “the idea is that 3-D printers could democratize design and eventually manufacturing by letting anyone make physical things in small quantities, without the expense of an assembly line.”

Read it at MIT Technology Review

Photo credit: Shutterstock.com